Introducing the Next Generation in Surface Science

Generation íí from KRÜSS

At KRÜSS we believe that interfacial chemistry has just scratched the surface. That’s why we are constantly engaging our intellectual capital and relentless curiosity to advance surface science in ways that advance our customer’s user experience. Case in point, the introduction of our Generation íí portfolio, which includes a new tensiometer, Tensíío, and a the first of its kind 3D Contact Angle measurement device for wettability, Ayríís.

Eliminate tedious, error-prone measurements from surface treatment validation

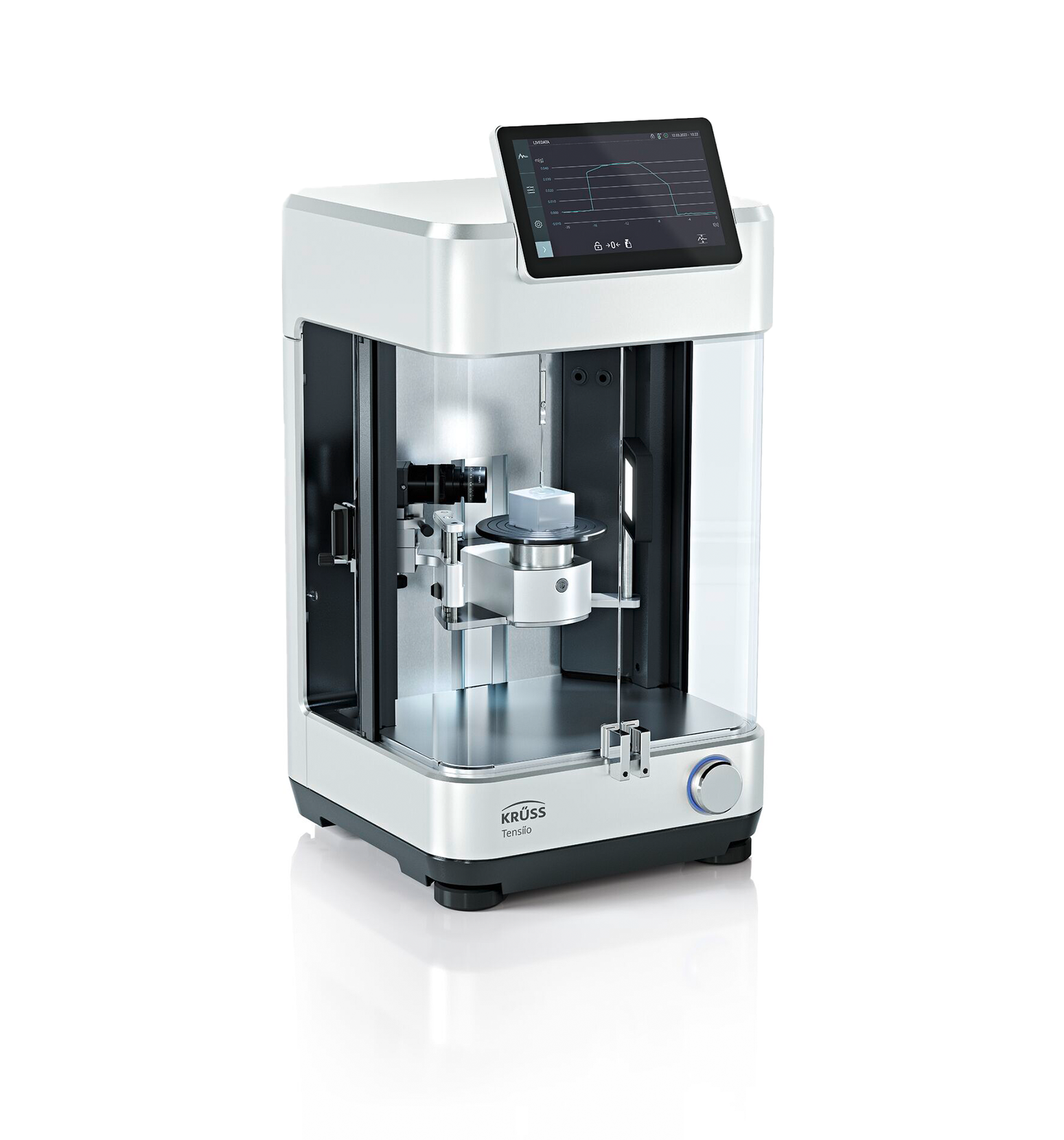

We Considered Every Angle to Increase Versatility, Usability and Accuracy.

Doing the work of 5 different instruments, the method diversity of our new tensiometer, Tensíío, delivers 15 different approaches for analyzing surface and interfacial tension, wettability and many other properties of your liquid, solid bodies, powders, and fiber samples. And we’ve purposefully designed it to be as versatile as the tasks you have to perform every day. It’s been engineered so you can easily add features as your needs change—growing as you grow, and only paying for what you need, when you need it.

Trade-in and Trade-up to the Next Level in Surface Science

With the introduction of Tensíío you also have the opportunity to upgrade your capabilities, no matter the brand of tensiometer you own through our new trade-up program with no extra charge.

In manufacturing, small errors can lead to big losses – lost time, money, and product. Ensuring consistent and correct surface treatment depends on precise, accurate measurements of variables like dyne levels (surface free energy). Dyne ink, a common surface treatment validation tool, is prone to errors because it relies on human interpretation and manual processes – telling only half the story.

Dyne ink opens the possibility for inconsistent, unreliable validation of a surface treatment’s effectiveness – which impacts the quality of the final product itself.

Effective surface treatment validation requires accuracy. Unfortunately, in an industry where dyne ink is the standard, error-free surface treatment validation feels like an anomaly. But it does exist.

Place. Click. Done.

With KRÜSS’s MSA, surface treatment validation is as easy as 1, 2, 3. The fully automated, one-click solution is so easy to operate, application errors are almost impossible. Simply place on the surface, click, and you’re done.

Ayríís: Surface Science In The Palm of Your Hand

Our new liquid 3D contact angle measurement device, Ayríís, is the first of its kind. Ayríís creates a virtual 3D model of the water drop dosed during measurement, then uses this spatial image to determine contact angle reliably. Designed to eliminate user error and results variability, it is ideally suited for use on the factory floor, with handheld mobility and functionality, and in just seconds Ayríís provides automatic self-checking for each result and definitive validation based on your own quality parameters. It requires no prior training, no added peripheral device and it’s ideal for analyzing large work pieces.

Easy to Use. Easy to Own.

We want to make owning Ayríís as easy as it is to use. So, we offer four ways to add Ayríís to your operations. It is available for a short-term lease, long-term lease, rent-to-own standard purchase. The opportunity to “try before you buy” reflects our confidence in the world-class performance we believe you will experience with Ayríís.

Remove the Guesswork

When it comes to manufacturing products that will work reliably, you need accurate surface treatment validation. Every time. This is where the Mobile Surface Analyzer (MSA) by KRÜSS steps in. Ensure accurate quality control with its fully automated design that calculates dyne levels (SFE) at the push of a button, without the risk of human error.In addition to accuracy, the MSA provides additional benefits to manufacturers, including:

- Ability to test multiple sections of a surface

- Allows for testing at different angles (overhead, horizontal or vertical)

- Provides results in seconds

- Collects and stores data in ADVANCE® software

- Ability to test in manufacturing facility versus a lab environment

Remove the Guesswork

When it comes to manufacturing products that will work reliably, you need accurate surface treatment validation. Every time. This is where the Mobile Surface Analyzer (MSA) by KRÜSS steps in. Ensure accurate quality control with its fully automated design that calculates dyne levels (SFE) at the push of a button, without the risk of human error.In addition to accuracy, the MSA provides additional benefits to manufacturers, including:

- Ability to test multiple sections of a surface

- Allows for testing at different angles (overhead, horizontal or vertical)

- Provides results in seconds

- Collects and stores data in ADVANCE® software

- Ability to test in manufacturing facility versus a lab environment

Let's Talk About It

Have questions? Want to learn more about Tensíío or Ayríís? Book a discovery call with one of our representatives.

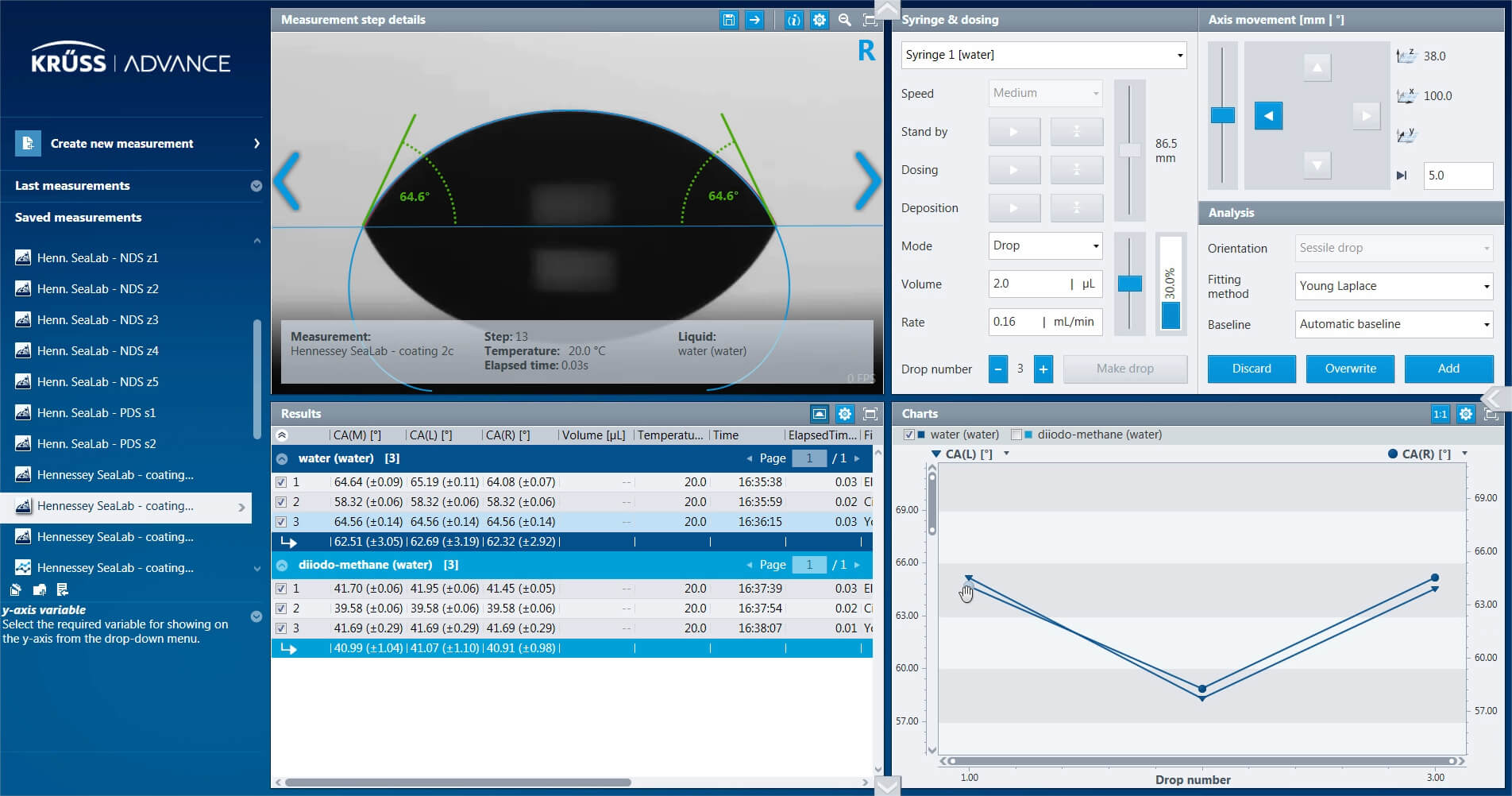

ADVANCE® your understanding

No more relying on handwritten notes and manual data entry. KRÜSS’s ADVANCE® software is intuitive and sophisticated, automatically capturing and storing all your complex measurement data.

Unrivaled in the industry, ADVANCE® is easy to use, includes automation capabilities, and provides complex measurements in seconds. ADVANCE® follows a universal workflow —preparation, perform, review, evaluate — that ensures every measurement is based in scientific principle. Its user-friendly interface eliminates multiple menus and pop-ups and guides you through each test — from sample prep to exporting your data. With the ability to automatically collect and store results from the MSA, it eliminates human error and keeps a record of historical data for future production cycles.

Same tool. Multiple applications.

When it comes to surface treatment validation, KRÜSS offers unmatched product breadth and depth of engineering. Our one-click MSA measures dyne levels (SFE) to enable quality control of pretreated, coated, or cleaned surfaces. Regularly regarded as among the most precise, accurate and easiest to use, the MSA can be used to cover a range of applications, including:

- Packaging

- Automotive

- Aerospace

- Medical devices

- Rubber, latex, polymers, adhesives

- Lamination, décor

- Paper, pulp

- Paints, inks, varnishes