Place. Click. Done.

With KRÜSS’s MSA, surface quality control is as easy as 1, 2, 3. Simply place on the surface, click, and you’re done. Ensuring your surface is properly prepared for coating, bonding, or adhesive application has never been easier.

Eliminate tedious, error-prone measurements from surface treatment validation

In manufacturing, small errors can lead to big losses – lost time, money, and product. Ensuring consistent and correct surface treatment depends on precise, accurate measurements of variables like dyne level (surface free energy). Dyne ink, a common surface quality tool, is prone to errors because it relies on human interpretation and manual processes – telling only half the story.

Dyne ink opens the possibility for inconsistent, unreliable validation of a surface treatment’s effectiveness – which impacts the quality of the final product itself.

Effective surface quality control requires accuracy. Unfortunately, in an industry where dyne ink is the standard, error-free validation feels like an anomaly. But it does exist.

In manufacturing, small errors can lead to big losses – lost time, money, and product. Ensuring consistent and correct surface treatment depends on precise, accurate measurements of variables like dyne levels (surface free energy). Dyne ink, a common surface treatment validation tool, is prone to errors because it relies on human interpretation and manual processes – telling only half the story.

Dyne ink opens the possibility for inconsistent, unreliable validation of a surface treatment’s effectiveness – which impacts the quality of the final product itself.

Effective surface treatment validation requires accuracy. Unfortunately, in an industry where dyne ink is the standard, error-free surface treatment validation feels like an anomaly. But it does exist.

Easy. Accurate. Intelligent.

Easy. Accurate. Intelligent.

With KRÜSS’s Mobile Surface Analyzer (MSA), get reliable results with the click of a button. The MSA eliminates the need for unreliable dyne inks and conclusively measures the reading of dyne level (surface free energy) across many manufacturing and R&D processes. By removing operator interpretation of results during measurement, the MSA ensures pass/fail validation every time. KRÜSS’s advanced technology allows for fast, repeatedly exact data in seconds that is automatically incorporated into the ADVANCE® software. Learn how KRÜSS can help you monitor your surfaces more effectively. Let’s talk.

Remove the Guesswork

When it comes to manufacturing products that will work reliably, you need accurate results without increasing production time. This is where the Mobile Surface Analyzer (MSA) by KRÜSS steps in. Ensure reliable quality control with its fully automated design that calculates dyne levels (SFE) at the push of a button, without the risk of human error.In addition to accuracy, the MSA provides additional benefits to manufacturers, including:

- Ability to test multiple sections of a surface

- Allows for testing at different angles (overhead, horizontal or vertical)

- Provides results in seconds

- Collects and stores data in ADVANCE® software

- Ability to test in manufacturing facility versus a lab environment

Remove the Guesswork

When it comes to manufacturing products that will work reliably, you need accurate surface treatment validation. Every time. This is where the Mobile Surface Analyzer (MSA) by KRÜSS steps in. Ensure accurate quality control with its fully automated design that calculates dyne levels (SFE) at the push of a button, without the risk of human error.In addition to accuracy, the MSA provides additional benefits to manufacturers, including:

- Ability to test multiple sections of a surface

- Allows for testing at different angles (overhead, horizontal or vertical)

- Provides results in seconds

- Collects and stores data in ADVANCE® software

- Ability to test in manufacturing facility versus a lab environment

ADVANCE® your understanding

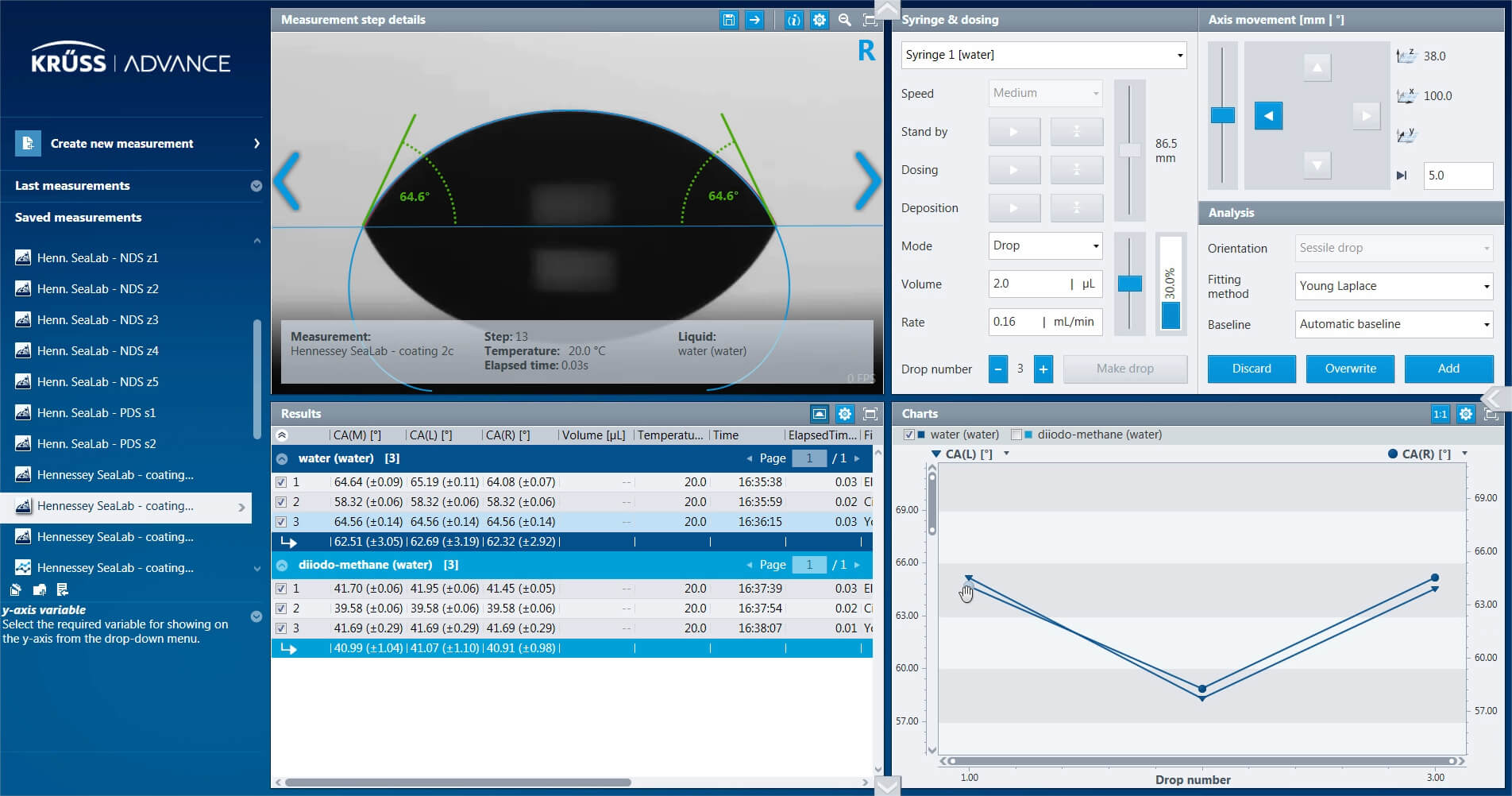

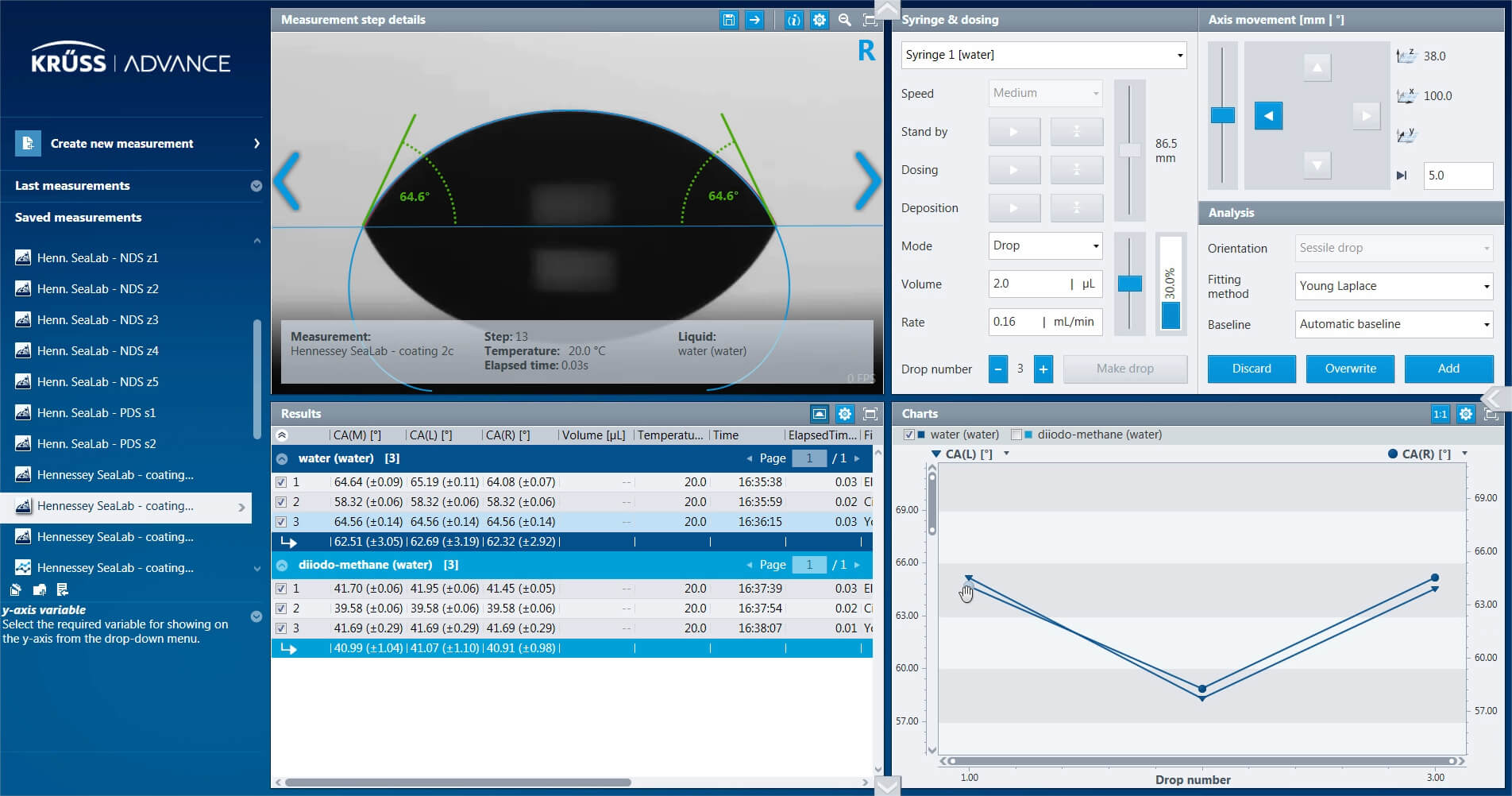

No more relying on handwritten notes and manual data entry. KRÜSS’s ADVANCE® software is intuitive and sophisticated, automatically capturing and storing all your complex measurement data.

Unrivaled in the industry, ADVANCE® is easy to use, includes automation capabilities, and provides complex measurements in seconds. ADVANCE® follows a universal workflow —preparation, perform, review, evaluate — that ensures every measurement is based in scientific principle. Its user-friendly interface eliminates multiple menus and pop-ups and guides you through each test — from sample prep to exporting your data. With the ability to automatically collect and store results from the MSA, it eliminates human error and keeps a record of historical data for future production cycles.

ADVANCE® your understanding

No more relying on handwritten notes and manual data entry. KRÜSS’s ADVANCE® software is intuitive and sophisticated, automatically capturing and storing all your complex measurement data.

Unrivaled in the industry, ADVANCE® is easy to use, includes automation capabilities, and provides complex measurements in seconds. ADVANCE® follows a universal workflow —preparation, perform, review, evaluate — that ensures every measurement is based in scientific principle. Its user-friendly interface eliminates multiple menus and pop-ups and guides you through each test — from sample prep to exporting your data. With the ability to automatically collect and store results from the MSA, it eliminates human error and keeps a record of historical data for future production cycles.

Same tool. Multiple applications.

Same tool. Multiple applications.

When it comes to surface science, KRÜSS offers unmatched product breadth and depth of engineering. Our one-click MSA measures dyne levels (SFE) to enable quality control of pretreated, coated, or cleaned surfaces. Regularly regarded as among the most precise, accurate and easiest to use, the MSA can be used to cover a range of applications, including:

- Packaging

- Automotive

- Aerospace

- Medical devices

- Rubber, latex, polymers, adhesives

- Lamination, décor

- Paper, pulp

- Paints, inks, varnishes

When it comes to surface treatment validation, KRÜSS offers unmatched product breadth and depth of engineering. Our one-click MSA measures dyne levels (SFE) to enable quality control of pretreated, coated, or cleaned surfaces. Regularly regarded as among the most precise, accurate and easiest to use, the MSA can be used to cover a range of applications, including:

- Packaging

- Automotive

- Aerospace

- Medical devices

- Rubber, latex, polymers, adhesives

- Lamination, décor

- Paper, pulp

- Paints, inks, varnishes

Accuracy at the push of a button

Accuracy at the push of a button

The MSA’s compact size allows it to be used directly on the manufacturing floor and enables it to work on different angled surfaces (overhead, horizontal, or vertical). Testing is also done automatically at the push of a button, so workers can test multiple areas of large parts to ensure consistency across the entire piece.

For surface treatment validation accuracy, precision, and repeatability across your manufacturing processes, partner with KRÜSS.

Never stop learning

At our core, KRÜSS and our customers share the same passion for discovery. Whether it’s our technology and innovative thinking or our courage to try what others won’t, we never stop learning and sharing new insights with each other.

If you’re driven by wonder and an unrelenting search for better, we should talk. We’d love to learn what inspires you and see how KRÜSS can take you further.